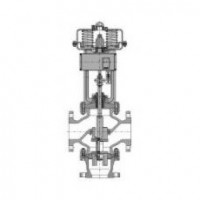

Designed for your production needs - we offer a full range of pneumatic, electric or hydraulic actuators. The thrust required to close the valve can be adjusted according to the user's needs.

Multifunctional positioner

The ARCAPRO® Intelligent Positioner provides a multifunctional port for the controller or process control system of the steam depressor. The positioner is installed directly into the actuator by the NAMUR standard, which ensures high precision stroke control without any return error and supports the standard 4-20mA signal. HART, Profibus, and Foundation fieldbus standards can be used to build digital interfaces with bidirectional data exchange, including status information. This means that the parameters of the locator can be set on site or remotely through the communication system. Other accessories can also be selected on the valve, such as accelerator, limit switch and solenoid valve, to meet the personalized needs of users.

Static and dynamic leak proofing:

We choose dynamic valve stem seal and static valve cover seal under the action of pressure, and comprehensive consideration of the stem surface treatment and packing material selection, fully meet your requirements of pressure and temperature range. The cavity design commonly used for bonnet seals prevents installation errors during service or maintenance. Self-sealing compression caps are used in high-pressure situations to ensure that the valve remains sealed no matter how much torque is applied to the bonnet screws. This design also ensures that the seat and spool are protected from any radial unbalance forces, thereby minimizing the possibility of internal leakage.

Diversified valve internals

Valve internals are key components for controlling pressure and temperature. Perforated fixed throttles are designed and manufactured specifically for flow conditions and the range required for regulation. The selected spray type can fully meet the temperature requirements of steam and damped water. In the occasion of higher safety requirements, a dirt screen is installed at the steam inlet to prevent the entry of contaminated debris and prevent it from happening. Patented, pressed seats ensure quick, simple, low cost maintenance without special tools.