|

Company

|

|||||||||||||||||||||||||||

Detail

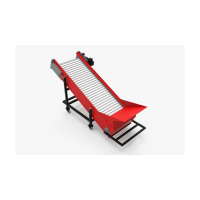

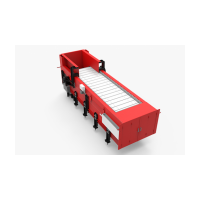

The vibrating fluidized bed cooler for bulk materials transfers the heat that needs to be lost in the cooling process through convection, namely direct heat transfer, so that the heat transfer medium and the product direct contact. The transmission in the cooler is carried out by a micro-throw motion known in the vibration transmission technique, which is individually designed for application and machine type by adjusting amplitude, frequency and connecting rod (throw Angle). Heat transfer is usually carried out through ambient air, but is also carried out using temperature controlled or regulated process air in special applications. According to the application, the cooler is divided into different cooling areas. Fresh air operation or exhaust gas return or partial air return can be carried out here. Versions with swing and stationary exhaust hoods are available. Vibrating fluidized bed coolers can be supplied in a variety of materials, including plain steel and stainless steel, or a combination of both.

more>New