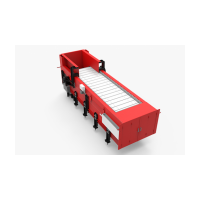

The frame of the machine base is bolted to the foundation. Depending on the system, only very low drive power is required. Because the dynamic restoring force of the working spring is mainly compensated by the shock absorber in the active mass compensation system, the dynamic residual force transmitted to the foundation is very low. Using this system, large vibration amplitude can be realized, so as to achieve high conveying capacity. The maximum technically reasonable length is about 70m. With these machines, the groove is always screwed to the groove support frame and can be replaced. Slider crank drive includes standard bearing seat, three-phase standard motor (pedal version) and V-belt drive. The machine design can also be curved. This type of machine is often referred to as a reader, casting area using a sorting and cracking chute. As the vertical acceleration value is less than 1 g, the conveying material will not rise in the conveying process. (Low noise/mild.) However, the heavy castings on the chute can also be moved or turned by the worker at the same time, thus ensuring ergonomic long-term labor saving.

|

Company

|

|||||||||||||||||||||||||||

Detail

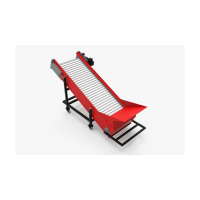

JOEST Double mass resonance conveyors are used to transport bulk and piece cargo over longer delivery distances. The oscillating system consists of a groove mass, a working spring and a periodic active shock absorber for subresonance excitation by an eccentric crank mechanism.

Like 0Hate 0Report 0

Favorite 0

Share 0

more>New