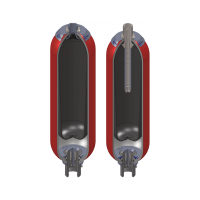

In the "AML" type accumulator, the separator can be replaced by unscrewing the ring nut on the gas side.

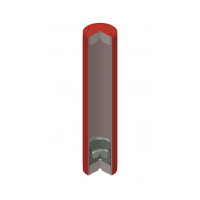

The diaphragm has very low friction, so the pressure drop between the oil side and the air side is irrelevant. The film also has low mass inertia. Therefore, diaphragm accumulators are preferred for use as water hammer absorbers and ripple dampers in the following domains: industry, machine tools, mobile, and agriculture.

The "AML" type accumulator has a recommended compression ratio of 1:6, and depending on the number of cycles, load and unload times can even reach 1:8 without compromising the use of nitrogen.