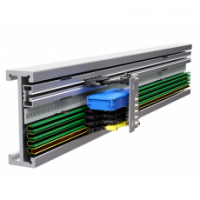

The "Peleg body slip wire" was invented by Paul Vahlesen in 1912. For the common moving cables of the time, problems with elasticity and expansion often resulted in poor contact and a large number of sparks, which often broke. Paul Vahlesen designed the barrel head and installed it on the "T" section steel with increased strength and tighter contact, resulting in a significant reduction in the running resistance of the copper-head steel body slip wire and carbon brush. Thus, prolong the service life of the sliding wire. Peleg body slide line design is compact and widely used in the following fields: steelmaking shop cranes, bridge cranes, container handling equipment, coke cars and many other applications. Peleg steel body slip wire current specification

Special requirements:

· Expansion or contraction due to temperature changes will be compensated by standard expansion fittings

· Peleg's steel sliding wire can be bent according to customer's specific requirements

· The heating system is applicable to all steel body slides of Peleg

· Slide line up to 3000Aatures on demand

Under the premise of not changing the structure of steel body slide wire, the engineers of Peleg use modern resources to continuously develop slide wire products so that its technical requirements can meet the needs of users in more areas.

Steel body sliding line is mainly used in: steel mills, coke plants, gas plants, cement industry, shipyard and dock companies, passenger transport systems.

· Steel body slip wire consisting of T-shaped steel and copper head conductor proved to be a classic product.

· T aluminum based rigid sliding wire, very economical because of the light weight of aluminum and the high conductivity of aluminum.

· T glass fiber slide wire is designed for corrosion or high humidity conditions.

· Pure copper guide rail is generally recommended for use in the case of large current load and high humidity.